Expires on {{ vipExpires }}

Expires on {{ vipExpires }}

Expires on {{ vipExpires }}

Expires on {{ vipExpires }}

(177) Add your review >

{{ finalPrice }}

{{ marketPrice }}

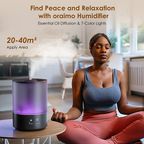

Size: 192*192*267.5mm

Product Material: PP

Weight: 1.15kg

Water Tank Capacity: 4L

Rated Voltage: DC 24V

Rated Power: 24W

*oraimo Lab test results

Model: OHM-501A

Dry Skin Symptoms Saver

L - Low mist volume: 100±20%ml/H

M - Medium mist volume: 200±20%ml/H

H - High mist volume: 300±20%ml/H

Essential Oil Diffusion & 7-Color Lights

Top-Fill Design

Tap to Control

Transparent Tank

Mist Mode & Timer Settings

Corrosion-Resistant PP Materials

Auto Shut-Off (When it's short of water)

(177 reviews)

Adding a review requires a valid email for verification

a.Faulty LED bulb. Open the base and replace the LED bulb.

b.Loose wire terminal. Disassemble the machine and reconnect the terminal securely.

The buzzer is faulty, but it does not affect the machine's functionality. You can choose not to repair it since the product works fine. Alternatively, disassemble the machine and replace the board with a functioning buzzer.

a.Faulty atomizing plate. Disassemble the base and replace the atomizing plate

b.Loose atomizing plate terminal. Disassemble the base and reconnect the terminal securely

c.Product not properly reset. Unplug the device.Dry the base thoroughly. Press the power button to deplete remaining energy. Reconnect the power and simultaneously press and hold the power and timer buttons for 5-8 seconds until you hear a beep and see the base flash, completing the reset.

d.Missing magnet at the bottom of the water tank. Install a magnet in the designated position at the bottom of the water tank for the machine to sense it.

a.Water entered the base through the air outlet during filling or emptying, damaging the PCB. If water is detected inside the base, immediately unplug the device.Place it in a dry and well-ventilated area for about 3 days to let it dry completely.Once dry, retry using the product. If the product still doesn't work, disassemble the machine and replace the PCB in the base.

b.Protective foam for the float was not removed. Remove the foam packaging from the float.

a.Spring valve rod at the bottom of the water tank is aged or damaged. Replace the spring, valve rod, and silicone with new ones.

b.Spring valve rod assembly is incorrectly installed. Reinstall the assembly correctly to fix the issue

a.Hall sensor malfunction. Disassemble the base and replace the PCB with a new one

b.Magnet on the water tank has fallen off or failed. Replace with a new magnet.

c.Water detection spring on the control board is misaligned. Disassemble the base and reposition the spring on the control boardc.

a.Water was added through the mist outlet, causing overflow in the base. Remove the water tank and empty the water in the base. Allow the base to dry completely before using it again.

b.Protective foam for the float was not removed. Remove the foam packaging from the float.

a.Water entered through the air outlet during filling or emptying, damaging the PCB. If water is detected inside the base, immediately unplug the device.Place it in a dry and well-ventilated area for about 3 days to let it dry completely. If the product still doesn't work after drying, disassemble the machine and replace the PCB in the base.

b.Base plastic parts are cracked or damaged due to dropping. Disassemble the product and replace the damaged plastic parts

c.Excess water around the product is mistaken as a leak. Place the product on a table and ensure the room has adequate airflow to avoid water accumulation.